Winter tire purchasing advice: how to choose the right product

- What You Need to Know

- The soft, elastic rubber compound of the winter tyres ensures not only more grip in cold conditions, but also better power transmission. Their sipe tread ensures better grip.

- The EU tyre label provides reliable information on fuel efficiency, wet grip and external rolling noise.

- A labelling code consisting of numbers and letters provides information about the width, cross-section and construction, among other things.

- According to a rule of thumb, the period from O to O, i.e. from October to Easter, requires winter-proof tyres. Anyone who drives with summer tyres despite wintry road conditions will pay a heavy fine due to the situational winter tyre requirement.

Play it safe with winter tyres

Snow, black ice and slush – when winter approaches, the roads become slippery. To ensure that drivers can continue to drive safely on the roads despite adverse weather conditions, it is necessary to change from summer to winter tyres every year at the onset of the cold season. However, the regular change is not only a nuisance, but also time-consuming. Those who live in regions with less snow may therefore wonder whether such an investment is worthwhile at all. The answer is clear: even in milder winter conditions, winter tyres are a must. While summer rubber compounds already reach their limits at single-digit plus degrees, causing the rubber to harden and lose grip, winter tyres are optimised for such temperature ranges. Their special sipe tread offers the best possible grip on snow and ice. So motorists should not save at the wrong end if they want to avoid an accident – especially since there is also a legal regulation that requires winter tyres to be fitted.

From O to O – time for a change

As soon as the first leaves fall, motorists start wondering whether it’s time to change their tyres. To avoid being caught off guard by a sudden change in the weather, it is advisable to act in good time. Although there is no legally stipulated day on which a change to winter tyres must be made, the winter tyre ordinance stipulates that a fitting is due with the first snow or the first slippery conditions. The ADAC advises changing tyres in autumn to avoid long waiting times at garages. In principle, however, it is still permissible to drive with summer tyres in winter when temperatures are mild and there is no snow or ice.

As a rough guide, there is also the so-called seven-degree rule: when the outside temperature drops to seven degrees Celsius, it is usually time to change from summer to winter tyres. Another rule of thumb is that the period from Easter to October (from E to E) poses the greatest danger from black ice and snow, which makes winter tyres necessary.

Compulsory in icy, slippery and snowy conditions: The Winter Tyre Ordinance

Section 2 paragraph 3a of the StVO states: “The driver of a motor vehicle may only drive it in icy, slippery, slushy, icy or frosty conditions if all wheels are fitted with tyres that meet the requirements of section 36 paragraph 4 of the Road Traffic Licensing Regulations, without prejudice to the general requirements for tyres.” This does not specify a specific period for fitting winter tyres, but only a so-called “situational winter tyre obligation”. This means that there is only an obligation when winter road conditions actually prevail. The following vehicles are exempt from this obligation:

- Commercial vehicles used in agriculture and forestry

- single-track motor vehicles (motorised two-wheelers such as motorbikes)

- Forklifts within the meaning of § 2 number 18 of the Vehicle Registration Ordinance (FZV)

- motorised ambulances as defined in § 2 number 13 of the Vehicle Registration Ordinance (Fahrzeug-Zulassungsverordnung)

- emergency vehicles of the organisations mentioned in § 35 paragraph 1 as well as special vehicles, as far as no tyres are available for these vehicles due to their design.

Special regulations apply to vehicles excluded from the situational winter tyre obligation: Before each journey, drivers must check whether the journey is really necessary.

Permitted, but daring: winter tyres in summer

By law, it is not forbidden to drive with winter tyres even in summer. However, seasonal tyres are specialised to meet the requirements of the different seasons. As the ADAC has proven in its winter tyre test, there is a safety risk when using winter tyres in the summer months. As the tyres soften at high temperatures, the tread blocks become unstable, the tyres deform and the rubber lies on the road. The increased rolling resistance also leads to higher fuel consumption. On dry road surfaces, winter tyres weaken especially when it comes to braking. This is because the braking forces are less easily transmitted to the road. The more tread depth the tyre has and the higher the ambient and asphalt temperatures, the longer the braking distance.

Compulsory winter tyres abroad?

The situational winter tyre obligation even applies to holidaymakers who are driving on German roads with their car registered abroad. In contrast, completely different rules often apply abroad:

- Austria: Just like in Germany, winter tyres are compulsory for slush, snow-covered roads and icy roads. Tyres must have a tread depth of at least five millimetres for diagonal tyres or four millimetres for radial tyres.

- Switzerland: Although there is no general obligation, fines may be imposed in the event of traffic obstructions due to unsuitable tyres.

- Italy: Due to the inconsistent regulations, it is advisable to enquire about the respective route before setting off.

- France: On some mountain roads, winter tyres with a minimum tread depth of 3.5 millimetres are compulsory. These routes are usually signposted accordingly.

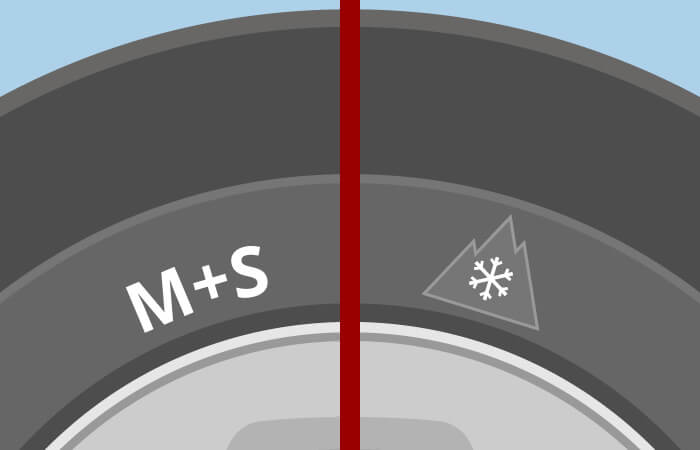

From “M+S” to snowflake

Until the end of September 2024, all winter tyres will be recognised as such if they are marked with the so-called “M+S” symbol and were manufactured before 2018. The abbreviation stands for the English phrase “Mud and Snow”. For identification purposes, there is either an “M+S”, “M*S” or “M&S” on the tyre. However, since the symbol is not legally protected, manufacturers can label any tyre with it – even if it is not suitable for winter use.

To close this legal loophole, tyres produced after 2017 must bear the so-called “Alpine” symbol to be considered winter tyres. Tyres bearing the snowflake symbol have passed a test for winter suitability and thus meet certain minimum requirements. The three-pointed mountain pictogram with the snowflake was introduced by the US Federal Highway and Vehicle Safety Administration (NHTSA). Thanks to the transition period until 2024, consumers do not have to replace their winter tyres immediately, but the ADAC recommends changing to Alpine tyres for safety reasons.

Attention, fine!

Anyone driving on the roads with summer tyres in winter weather conditions is committing an administrative offence and must expect a fine of 60 euros and a point in Flensburg. If the driver also obstructs traffic, he or she risks a fine of 80 euros and a point. If the driver endangers traffic, the fine increases to 100 euros. If the driver has an accident because of the wrong tyres, a fine of 120 euros is incurred. A comparatively small fine is also imposed on anyone who has affixed their winter tyre sticker inside the vehicle and is stopped by the police.

In addition to the fine, anyone who drives without winter tyres on ice and snow must reckon with repercussions for their insurance cover. In the event of an accident, for example, the insurance company may reduce the payment of the comprehensive insurance.

Construction, advantages and types: Everything about winter tyres

The adverse conditions on snow-covered roads make driving in winter considerably more difficult. During this time, secure traction, directional stability and precise power transmission are indispensable – characteristics that every winter tyre should have. But what distinguishes winter tyres from the summer version?

An advantage in wet and icy conditions: the structure of a winter tyre

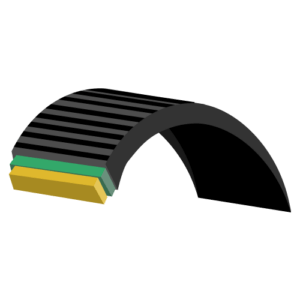

Winter tyres are made up of the following components:

- The tread: The top layer of a tyre has a tread pattern and makes contact with the road surface.

- The carcass: As the supporting structure of the tyre, it consists of up to two layers of fabric embedded in the rubber, a combination of synthetic fibre, silk and steel cord.

- The sidewall: This is the outer protection of the carcass. It shows the tyre size, the manufacturer and the production date.

- The bead: The inner ring helps to prevent the tyre from slipping on the rim.

- The inner layer: A rubber coating on the inside prevents air from escaping.

Drivers optimise safety with further equipment elements such as a rim protection strip or spikes. A rim protection strip made of reinforced rubber material, for example, prevents the rim from coming into contact with the kerb and thus prevents any damage. Winter tyres that are designed to be fitted with studs can be fitted with equipment elements in a workshop. They additionally improve the tyre’s grip and are used in particular when conventional winter tyres would fail on snowy roads.

It’s all in the mix: The material

Specially designed for cool temperatures (up to seven degrees Celsius) and wet conditions, winter tyres are not susceptible to hardening and offer more grip in the cold seasons than the summer variant. Due to their softer, more elastic rubber compound, they not only ensure more grip in cold conditions, but also better power transmission to the ground.

The thermo-elastic tread compound made of fillers such as carbon black or silica (silicic acid), natural rubber as well as various oils, resins and plasticisers continues to maintain grip at cold temperatures, adapts to the surface structure of the road and creates micro-interlocking. As a result, the tyres grip even on rain-soaked roads. The carcass, a fabric made of steel wire and nylon, also ensures optimised driving characteristics. However, due to the softer rubber compound, winter tyres wear out faster than the summer version.

The right tread

In addition to the material composition, their tread also distinguishes them from summer tyres. For tyres to grip properly in slush and snow, they must have a deep tread. Otherwise, the vehicle loses grip, which restricts steering behaviour and increases the braking distance. Although the legally prescribed minimum depth for winter tyres is only 1.6 millimetres, the ADAC recommends a tread depth of at least four millimetres for safety reasons.

The tread consists of up to 2,000 clearly recognisable sipes, i.e. tread incisions, which are arranged in a honeycomb, straight or wavy pattern, depending on the manufacturer. Thanks to the greater overall length, particularly effective interlocking with the slippery subsoil of the road surface is possible, for example in snow or slush. During the rolling movement of the tyres, the sipes open and penetrate the snow under the wheel load. Their block-like arrangement in longitudinal and transverse edges prevents ice and snow from sticking to the tread. Compared to summer tyres, winter tyres have more traction and lateral grip as well as shorter braking distances. At a speed of 80 kilometres per hour, for example, a car with summer tyres would only come to a halt 42 metres later.

Without a rim, as a complete wheel or the safety variant?

There are three different types of winter tyres:

Winter tyres

Winter tyres without rims are suitable for all drivers who already have rims. However, if you only have one set of rims for summer and winter tyres, you would have to have the winter tyres fitted and removed at a workshop. This is not only inconvenient, but also expensive. Tyre prices vary between 15 and 870 euros; the costs of the rims and the tyre change may have to be added. The leading manufacturers currently include Goodyear, Semperit, Hankook, Nokian, Continental and Pirelli.

Complete winter wheels

The combination of tyres and rims is a convenient solution for car drivers. Be it sturdy and at the same time inexpensive, but visually rather inconspicuous steel or expensive design rims made of aluminium – they are very practical in any case. Another advantage is that consumers can change the tyres themselves, which saves them the costs of the workshop. Prices for complete wheels range from 70 euros for bargains to about 2,500 euros for luxury models.

Runflat winter tyres

Thanks to their run-flat properties, users can drive on to the nearest workshop in the event of a puncture. A tyre pressure monitoring system alerts the driver to the loss of pressure. Since the self-supporting, reinforced sidewall does not collapse and slip off the rim in the event of a pressure loss, a distance of up to 80 kilometres is possible at a speed of no more than 80 kilometres per hour. Runflat tyres can be recognised by the abbreviations CSR, DSST, HRS, RFT, ROF, SSR, SST, XRP and ZP. With an average cost of between 50 and 400 euros, they are somewhat more expensive than ordinary winter tyres.

All-season tyres – an alternative?

If you don’t want to change your tyres every year, you can use all-season tyres, also known as all-weather tyres. If they bear the “M+S” marking, they are also approved for winter road conditions. All-weather tyres combine the longitudinal grooves of summer tyres with the block tread of winter tyres, so they are suitable for warm temperatures as well as snow and ice. However, all-season tyres reach their limits when exposed to large amounts of water. In addition, they wear out more quickly in summer and consume more fuel. All-season tyres are therefore only a compromise and are mainly suitable for areas with less snow or for city drivers.

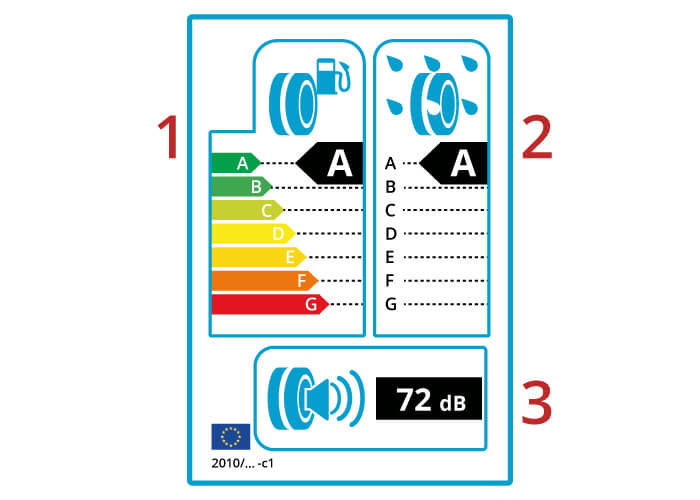

EU label, DOT number and ECE test mark as decision-making aids

Many consumers do not immediately find their way through the tyre jungle, which is why they find it difficult to make a purchase decision. This is made easier by the EU tyre label, which provides information on the respective force efficiency, wet grip and external rolling noise. The ECE test mark shows that the components of the tyre have passed all the prescribed tests. Finally, the DOT number provides information about the manufacturer’s date and thus the age of the tyres.

A plus in safety with the EU tyre label

The EU tyre label provides information on the most important measured values. According to the European Tyre Labelling Regulation, since 1 November 2012 all motor vehicle tyres must include a label indicating the fuel efficiency class, the wet grip class and the external rolling noise class, including the measured value. This so-called tyre label is to be attached either as a sticker on the tread or as a printed label. The aim is to make drivers more aware of safety, environmental protection and economic efficiency in road traffic.

In addition, the EU tyre label informs consumers about the most important purchase criteria, such as service life and driving stability as well as aquaplaning and braking properties. The classification is done on a coloured scale ranging from A, the best category (green), to G (red). The tyre label applies to car, truck and transport tyres, but not to retreaded tyres, tyres without road approval, T-road tyres, vintage tyres, motorbike tyres, earthmover tyres and farm tyres.

Fuel efficiency

The fuel efficiency of a tyre depends entirely on its rolling resistance. This means that the lower the rolling resistance, the less fuel drivers consume. The classification is made into classes A, the highest efficiency, to G, the lowest efficiency, with the letter D being unassigned to better distinguish higher quality models from tyres with a lower performance level. Each letter increases fuel consumption by 0.1 litres per 100 kilometres. When using A-rated tyres, drivers consume up to 7.5 percent or 0.66 litres per 100 kilometres less compared to G-rated tyres. The heavier the movement, i.e. the higher the rolling resistance, the more energy or fuel is consumed.

Wet grip

Among other things, the wet grip of the tyres is decisive for driving safety. This is the length of the braking distance on wet roads. On the tyre label, the driving characteristics in the wet and at a speed of 80 kilometres per hour are divided into classes A (green) to G (red) respectively, whereby neither D nor G are occupied. The difference from one class to the next is between three and six metres, so that the braking distance difference between the best and the worst category is over 18 metres. Since tyre pressure is also responsible for wet grip, consumers should check it regularly.

External rolling noise

The external rolling noise rating is the decibel value that occurs at a rolling speed of 80 kilometres per hour. The value refers to the perceived volume when driving past. Tyres are also classified in terms of external rolling noise. In addition, the noise classification is shown as a pictogram. The more black bars, i.e. sound waves, the higher the volume:

- Three bars: Compliance with the EU limit value.

- Two bars: Compliance with or below (up to three decibels) the EU limit value.

One bar: more than three decibels below the EU limit value.

For a passenger car, the lowest value is approximately between 67 (narrow tyres) and 71 decibels (wide tyres), the highest between 72 and 76 decibels. Since the noise emission affects the overall volume of the vehicle, a higher value not only affects driving comfort, but also pollutes the environment. For comparison: 75 decibels corresponds to the volume of a hoover.

Well-tyred: the ECE test mark

The ECE test mark has been compulsory since the production date of 1 October 1998 and informs tyre owners about compliance with the European standard ECE-R 30, i.e. compliance with certain limit values regarding wet grip, noise emission and rolling resistance. It is located as an “E” in a circle or as an “e” in a rectangle on the tyre sidewall. The number next to it refers to the country of registration. If the marking is missing, the TÜV classifies this as a “serious defect” during the general inspection.

Determine the age of the tyre: The DOT number

Apart from weather influences such as moisture and frost, abrasion is also responsible for tyre wear. With increasing age, the rubber in winter tyres hardens so that the tyres can no longer fulfil their purpose properly. Tyre age is therefore a decisive safety factor. At worst, driving instability can suffer and lead to a breakdown.

The so-called DOT number, which is stamped on the tyre sidewall, provides information about the age of a tyre. The abbreviation stands for “Department of Transportion”, the United States Department of Transportation, which introduced this marking. The manufacturer’s date, also known as TIN (Tire Identification Number), is a four-digit number in an oval at the end of the DOT number. While the first two digits provide information about the calendar week, the last two stand for the year of production. For example, if the DOT number is 3809, the winter tyre was manufactured in mid-September 2009.

Although an age statement must be recorded on each tyre, it is nevertheless permissible for dealers to declare their tyres as new even after five years if they have been stored properly. From the age of six years, tyres should be checked regularly for cracks and other damage. If stored properly, winter tyres often last up to ten years according to the manufacturer, but should be replaced after eight years at the latest.

Width, cross-section and co.: Finding the right tyre size

Since the choice of winter tyres on the market is unmanageable, many drivers wonder how to find the right tyres. Basically, a certain type is prescribed for each vehicle model or, depending on the manufacturer, the size of which is ideally matched to ensure that safety and functionality – from power transmission to driving stability to load movement – can always be guaranteed. In addition to the safety risk, mounting without approval is also associated with fines.

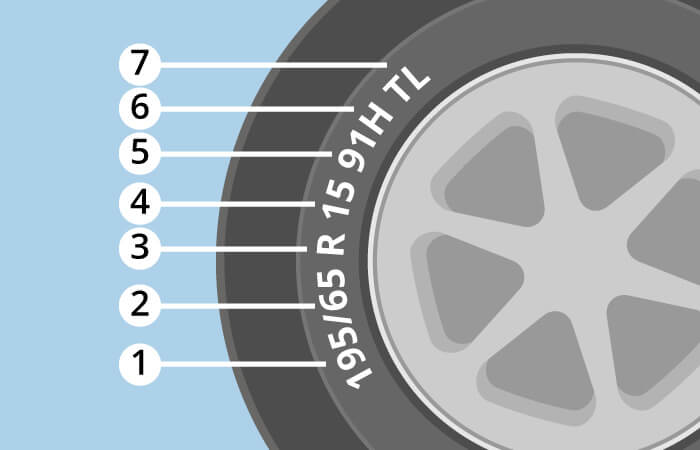

Consumers can find the relevant information in the vehicle registration documents, more precisely the CoC paper (Certificate of Conformity), under point 15 as well as directly on the tyres. On the side walls of the tyre there is various information in the form of rows of numbers and letters. An identification code gives information on the rim diameter, aspect ratio, tyre width, load index and speed index and could be, for example, 205/55 R16 81V, which means the following when broken down:

- 205: The tyre width in millimetres

- 55: The aspect ratio (height to width) in percent

- R: The construction type (in this case radial tyres)

- 16: The rim diameter in inches

- 81: The load index as a numerical code

- V: The speed index, i.e. the maximum permissible speed.

But what do the different values mean in detail? The following list provides information on tyre width, cross-section and co.

Tyre width

The tyre width is given in millimetres. Standard passenger car tyres are between 125 and 335 millimetres wide, with the values increasing in ten-millimetre increments. However, as a rule, the actual width differs from the nominal specifications by a few millimetres, depending on the manufacturer. While wide winter tyres are more suitable on packed snow, but also on dry roads, in terms of cornering behaviour and braking potential, narrower variants are ideal on loose fresh snow. The larger contact area of wide winter tyres provides more grip and thus better acceleration and a shorter braking distance. At the same time, however, wider tyres also pose a risk of aquaplaning. In addition, the increased rolling resistance not only increases rolling noise, but also fuel consumption.

The tyre cross-section

The tyre cross-section indicates the ratio between tyre height and tread width and is given as a percentage. For example, “/50” (referred to as series 50 or 50 tyres) means that the tyre height is half the tyre width. Wide tyres tend to have a low cross-section. The wider the tread, the flatter the tyre sidewall. To cope with potholes safely, tyres with a low cross-section need a higher air pressure. The larger the cross-section, the larger the outer circumference of the complete wheel.

Tyre construction

Tyre construction refers to the structure of the carcass. A distinction is made between bias-ply tyres, bias belted tyres and radial tyres, with radial now being the standard type. Instead of the “R”, sometimes only a dash, i.e. “-“, is indicated. All tyres on a motor vehicle must be of the same type; mixed tyres are not permitted.

Rim diameter

The rim diameter is measured radially from rim edge to rim edge and is expressed in inches. The diameter is usually 10 to 20 inches or 315 to 440 millimetres. Winter tyres have a particularly high aspect ratio with a good suspension effect.

The load index

The load index, also called load index (LI) or load capacity index, indicates how much weight a tyre can carry. Each LI value is assigned a specific maximum weight at a given inflation pressure. If the LI is 78, for example, the maximum permissible load is 425 kilograms. Tyres with a particularly high load capacity are declared as “Reinforced”, “Extra Load” or “XL” and can be found on vans, vans or off-road vehicles, among others. In addition to the driving speed, the tyre pressure also has an influence on the load capacity of the tyres. For example, it decreases with decreasing air pressure and increased speed.

The speed index

The speed index (GSY) indicates how fast consumers are allowed to drive with their tyres. The labelling is based on a letter scale. For example, “G” stands for 90 kilometres per hour. The values range up to a speed of 270 kilometres per hour (W). It should be noted that the speed and load index must always be considered in conjunction with each other. The higher the speed index, the lower the load capacity. Unlike summer tyres, winter tyres may also have a lower speed index. Passenger car tyres with a cross-section of 45 percent or less and a speed index of at least V are also called ultra-high performance tyres (UHP tyres).

Images 1-14: © FinalCheck

1,816 reviews

1,816 reviews